Federal Conveyor Belting

The Federal line of conveyor belting gives high performance, long lasting service in bulk-haulage and bucket elevator applications under the severest operating conditions. This is a result of Federal’s special combination of tough synthetic fabric plies, superior adhesions and protective covers designed for specific belt applications.

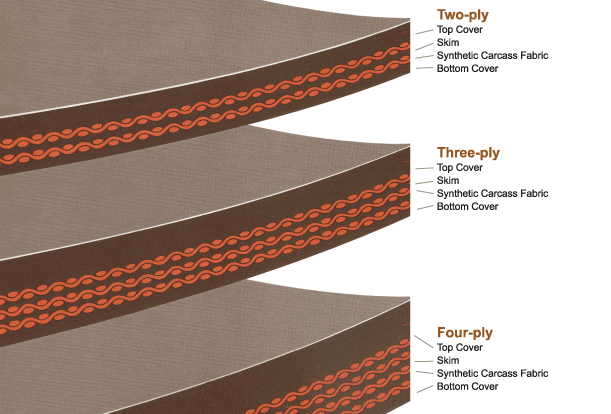

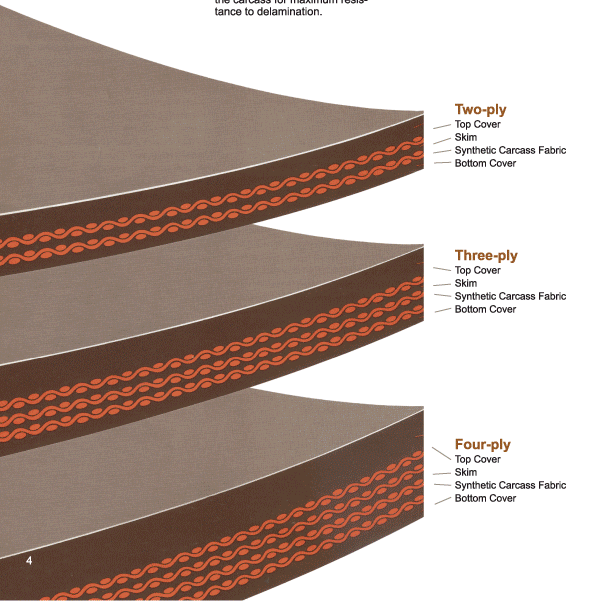

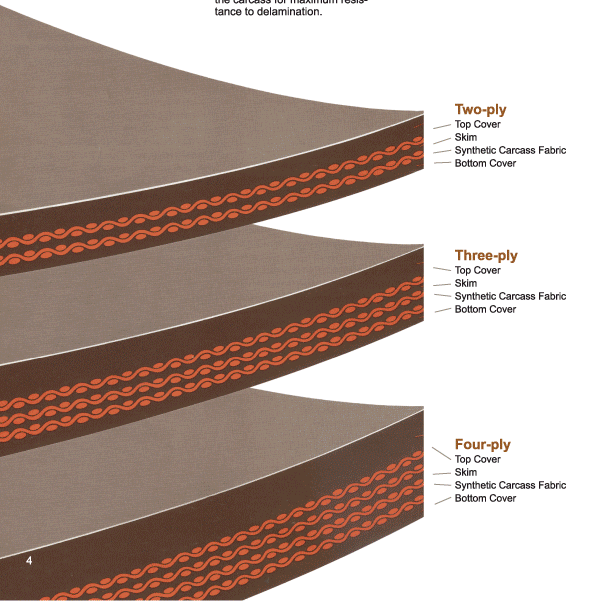

In conventional multiple – ply belting, the weight of the belt increases in direct proportion to the increase in the number of plies. The belt gets heavier and bulkier as plies are added. Federal’s unique construction concentrates high strength in fewer plies so that the belt can be made with less weight and thickness than multiple-ply belts. This makes Federal Belting more flexible so that it can travel easily over smaller pulleys. The reduction in weight makes it easier to install and saves on the energy needed to drive the belt.

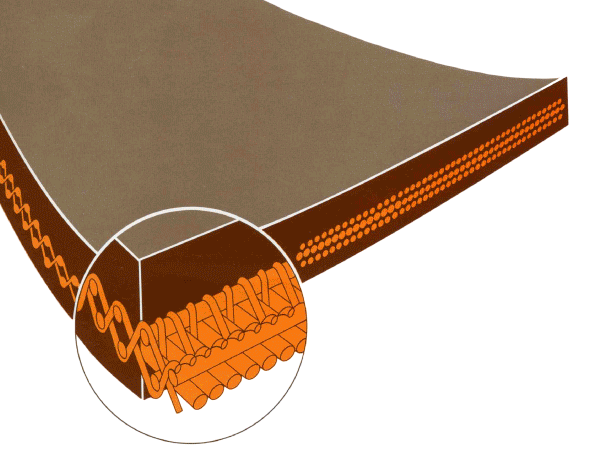

Federal Belting is available with a wide variety of specially-compounded rubber covers for a full range of general and special service requirements. These have been developed to provide superior long-wearing carcass protection and maximum overall belt performance. Additional belt serviceability is afforded by the high strength synthetic fabric used in the Federal carcass. It has optimum resistance to stretch, resists chemical attack , has only one-tenth the water absorption of nylon and does not become stretchy when wet. The synthetic carcass is also engineered for high impact, tear and rip resistance and the fabric is chemically bonded to the rubber for high resistance to delamination. Federal’s outstanding features provide long-service life in bulk-haulage conveyor and bucket elevator applications, assuring you of tip value for your conveyor belting dollar.

Federal Conveyor Belting for Every Application

In addition to the streamlined belting, Federal manufactures a complete modernized line of conventional multiple-ply belting. And of course, there is Federal’s premium performance UniPly belting which is also in a fire resistant version, Mine-UniPly belting. For higher tension service, there is Mine II belting, plus our line of Steel Cord Belting provides total coverage of the low tension portion of conveyor belting requirements.

Multi -Ply – Belting

Our line also includes conventional multiple – ply belting for various applications. Multiple -ply belting is available from Federal in the full range of tension ratings, MP-35 to MP-240. Multiple -ply belting is also available in fire-resistant style to meet MSHA fire resistant requirements.

Uniply Belting

Belting for conveyors and bucket elevators uses Federal’s exclusive straight-warp carcass construction. A strong, tough, rip-resistant belting designed for conveyors and bucket elevators demanding the highest perfomance standards. Available with tensioin ratings to 550 piw for style C cut-edgge belting and to 1500 piw for Style M molded -edge belting.

Mine – Uniply for Fire-Resistant Applications

The exclusive Federal straight-warp carcass construction is available in MIne-Uniply Belting. It is especially designed for fire-resistant applications in both above and under ground service. Also, MSHA requirements for fire resistance. It is available in Style C cut-edge belting for tension ratings to 500 piw, and Style M molded-edge belting for rating to 1500 piw.

Steel Cord Belting

For high tension service to above 5000 piw, Federal offers Steel Cord Conveyor Belting. Available with RMA Grade 1 or 2; MSHA Fire-Resistant; and Oil Resistant covers.

Light Weight Belting

Federal manufactures Light Weight Belting for all types of applications such as package handling belting, Steep Grade belting for inclines to 45 degrees, and food handling belting that meets FDA and USDA Federal Meat and Poultry requirements.

Rated Operating Tension (Pounds/inch of width – piw)

| Federal | |||||||

|---|---|---|---|---|---|---|---|

| Belt Style | 2150 | 2220 | 3330 | 4440 | 3600 | 4800 | 5100 |

| Plies | 2 | 2 | 3 | 4 | 3 | 4 | 5 |

| Mechanical Fasterner | 150 | 220 | 330 | 385 | 440 | 550 | 720 |

| Vulcanized Splice | 150 | 220 | 330 | 440 | 600 | 800 | 1000 |

Belt Thickness

| Straight-Warp Grain 1 (Pounds/inch of width-piw) | |||||||

|---|---|---|---|---|---|---|---|

| Belt Style | 2150 | 2220 | 3330 | 4440 | 3600 | 4800 | 5100 |

|

Carcass thickness

|

.114 | .164 | .212 | .258 | .237 | .326 | .415 |

INDUSTRIAL SERVICES

Specs

Belt Weight

Heat Resistant.052.060.083.117.111.153194All others.053.061.084.118.111.153194

| Carcus weight Factors | |||||||

|---|---|---|---|---|---|---|---|

| Belt Style | 2150 | 2220 | 3330 | 4440 | 3600 | 4800 | 5100 |

|

Oil Resistant

|

.059 | .066 | .092 | .129 | .117 | .162 | .206 |

Cover Weight Factors

Heat Resistant.028.042.056.070.084.098.112.126.140.154.168.182.196.210.224All others.032.048.064.080.096.112.128.144.160.176.192.208.224.240.256Federal Mine.042.063.084.105.126.147.168.189.210.231.252.273.294.315.336

| Cover thickness | 1/16″ | 3/32″ | 1/8″ | 5/32″ | 3/16″ | 7/32″ | 1/4″ | 9/32″ | 5/16″ | 11/32″ | 3/8″ | 13/32″ | 7/16″ | 15/32″ | 1/2″ |

| Oil Resistant | .036 | .054 | .072 | .090 | .108 | .126 | .144 | .162 | .180 | .198 | .216 | .234 | .252 | .270 | .288 |

INDUSTRIAL CONTROL

Recommended Minimum Pulley Diameters for Vulcanized Splices

| Straight-Warp Grain 1 (Pounds/inch of width-piw) | ||||||

|---|---|---|---|---|---|---|

| Belt Style | C175 | C220 | C300 | C350 | C400 | C500 |

| Idler Trough Angle | 36 | 54 | 60 | 72 | 72 | 72 |

| 20° / 35° / 45° | 30 | 42 | 54 | 60 | 66 | 72 |

| 30 | 36 | 42 | 48 | 54 | 60 |

Troughability Data

| Straight-Warp Grain 1 (Pounds/inch of width-piw) | |||||||

|---|---|---|---|---|---|---|---|

| Belt Style | C175 | C220 | C250 | C300 | C350 | C400 | C500 |

| Idler Trough Angle | 12 | 14 | 14 | 14 | 18 | 18 | 24 |

| 20° / 35° / 45° | 14 | 20 | 20 | 24 | 24 | 24 | 30 |

| 16 | 24 | 24 | 24 | 24 | 24 | 36 |